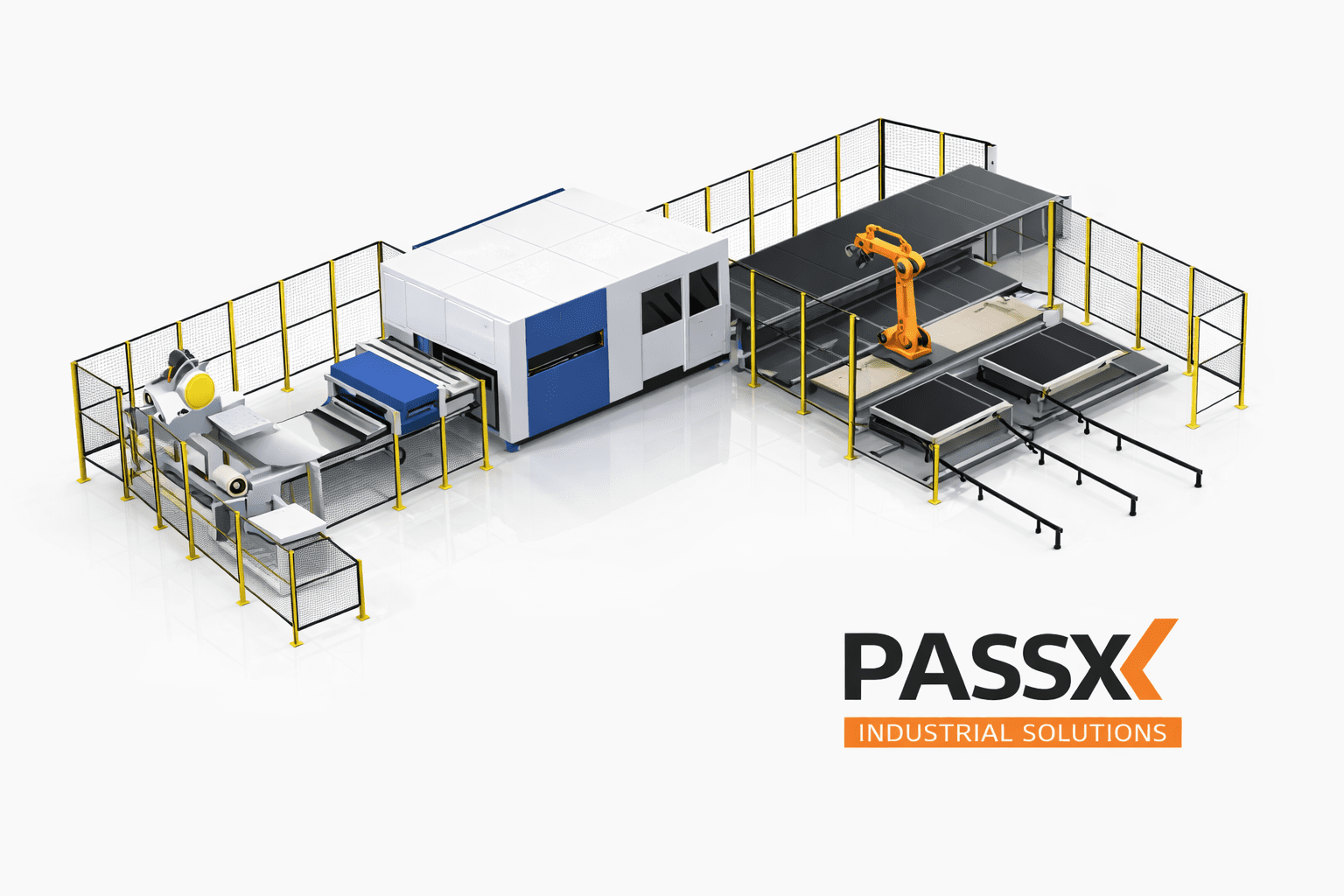

Passx is redefining the traditional approach to cutting, marking, and bending panels for E-House cladding by fully integrating advanced laser and automation technologies into a single, intelligent production workflow. High-precision laser cutting ensures consistent accuracy, while automated marking enables part numbering and barcode identification for complete traceability throughout fabrication and assembly. Robotic systems handle material movement and automatically feed bending cells, drastically reducing manual handling and process variability. By combining robotics with a fully integrated AS/RS sheet storage and retrieval system, Passx has achieved up to 85% labor savings, faster throughput, and unmatched production consistency—an efficiency level that would not be possible without intelligent automation at every stage of the process.

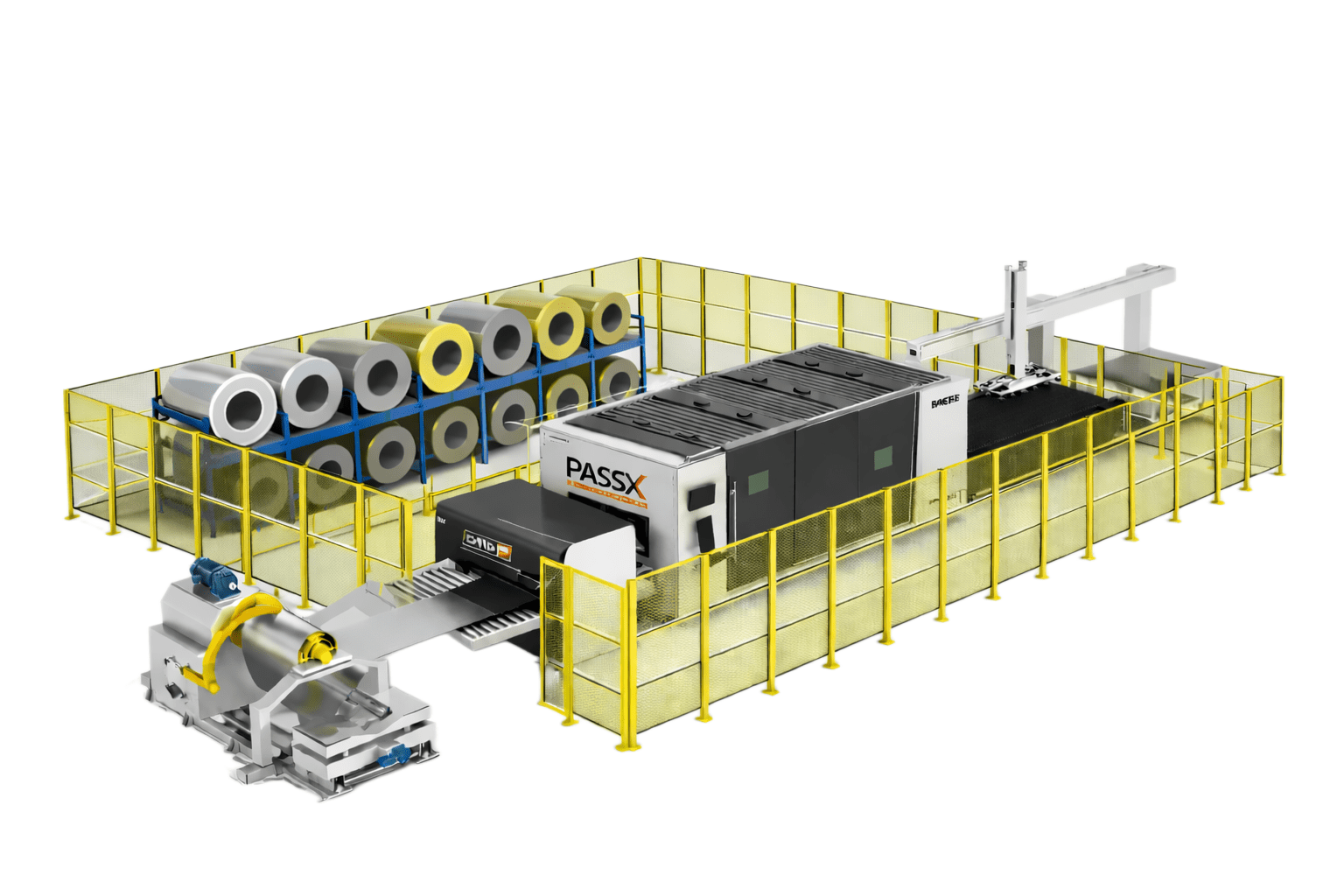

Coil-to-Sheet Laser Blanking is an advanced sheet metal processing technology that converts metal coil directly into precision-cut sheets and blanks using high-power fiber lasers. By eliminating traditional mechanical blanking and shearing, this process delivers greater flexibility, higher accuracy, and reduced material waste. In panel manufacturing, laser blanking enables the production of complex geometries, variable sheet sizes, and clean edges without tooling changes. This makes it ideal for architectural panels, electrical enclosures, HVAC panels, and industrial cladding applications.

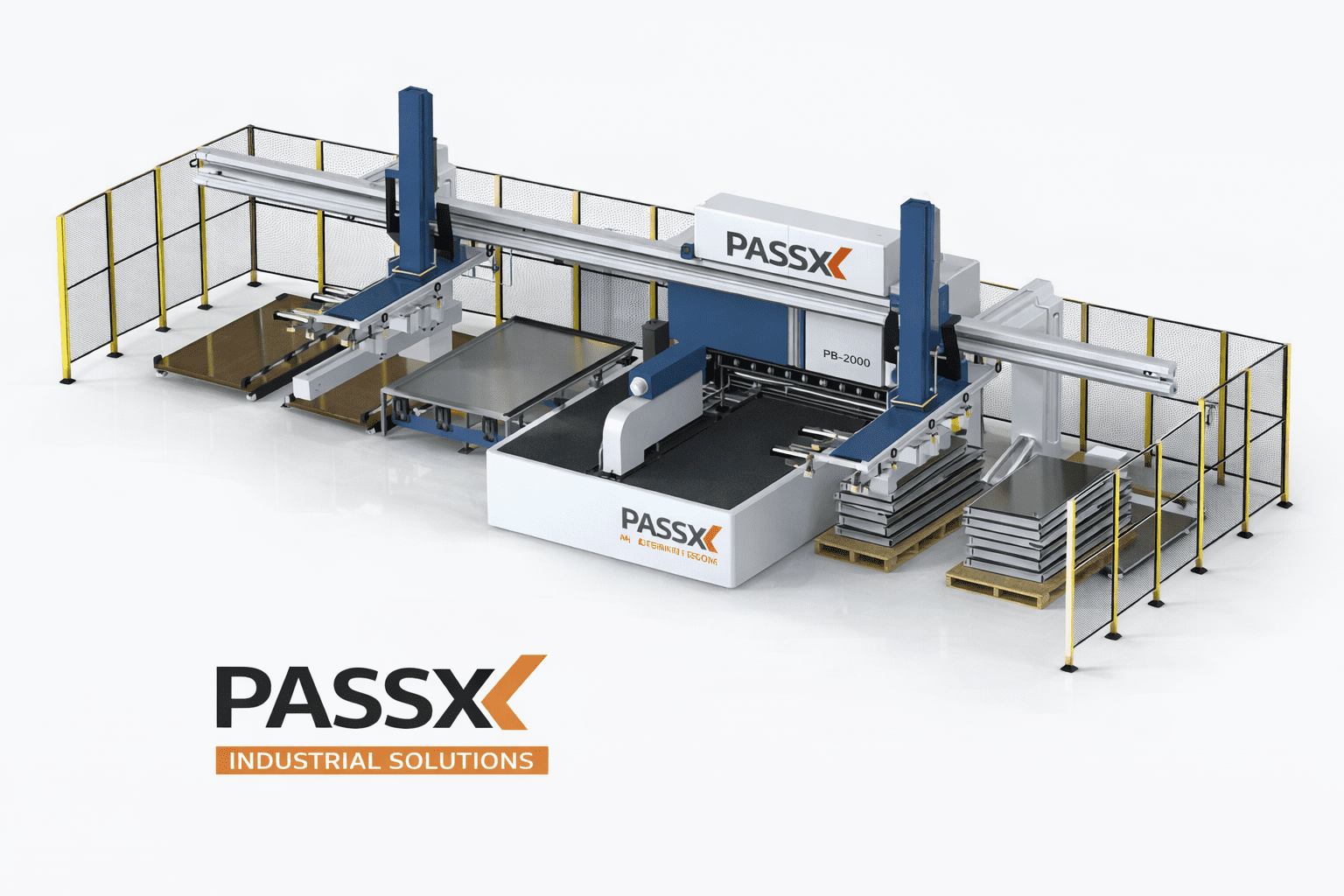

integrates high-precision press brakes with robotic handling to deliver accurate, repeatable bending with minimal manual intervention. Robots automatically load, position, and unload parts, ensuring consistent bend quality and eliminating operator-dependent variability. This automation supports complex multi-bend geometries, tight tolerances, and fast changeovers for both high-mix and high-volume production. By improving safety, reducing labor requirements, and synchronizing with laser cutting and material handling systems, robotic press brake forming increases throughput and delivers reliable, high-quality panels for E-House construction, electrical enclosures, HVAC systems, and architectural cladding applications.

Autonomous Mobile Robots (AMRs) automate material movement between machines, eliminating manual handling and reducing reliance on forklifts and labor. By delivering parts just in time to laser cutting, bending, and assembly stations, AMRs keep production flowing, minimize downtime, and improve safety. When integrated with AS/RS and robotic forming cells, AMRs enable flexible, lights-out manufacturing and can deliver 60–85% labor savings with higher throughput and consistent output.

(AS/RS) centralize and automate coil and sheet storage, enabling fast, accurate, and just-in-time material delivery to laser cutting and panel forming lines. By eliminating manual searching, crane handling, and staging delays, AS/RS ensures the right material reaches the coil-to-panel laser exactly when needed. Integrated with production planning, robotics, and AMRs, AS/RS reduces floor space, prevents material damage, improves inventory accuracy, and significantly increases throughput—making high-efficiency, low-labor panel manufacturing possible.

High-performance machinery ensures repeatable, consistent results.

Reduce waste and downtime with optimized workflows and smart automation.

Systems configured for diverse materials and a wide range of project demands.

Backed by training, maintenance, and lifecycle support.